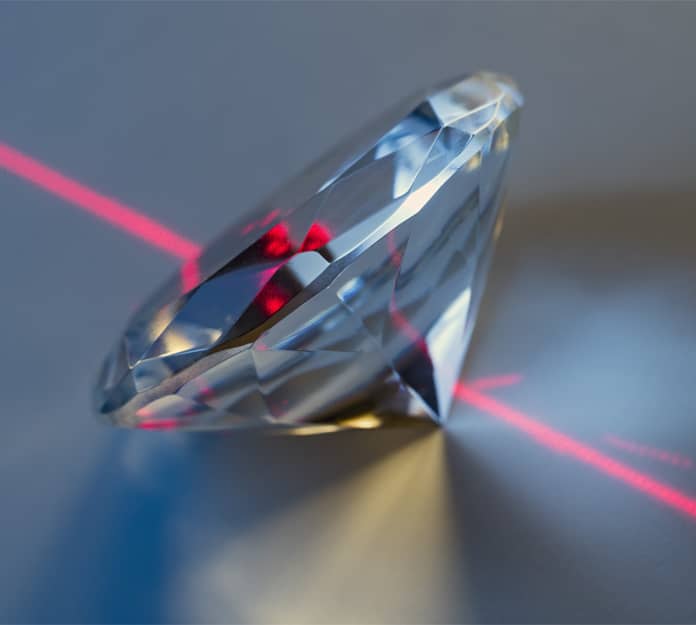

Advanced Diamond Inscription With PhotoScribe’s Cutting-Edge Technology

For the past 3 decades, PhotoScribe has worked alongside the industry’s top leaders providing a variety of solutions for diamond inscription. With our SurfaceScribe™ and PermaScribe™ technology, we mark natural and lab-grown diamonds on or below the surface with unique identifiers. With the mission to boost security in the supply chain, we’re constantly innovating to strengthen the industry’s reputation and solidify consumer trust.

Branding, Personalization, Serialization,

and supply chain Security are among the compelling reasons for marking diamonds.

Why Use Laser Technology?

- Unique Product Identification & Differentiation

- Quality Assurance

- Supply Chain Security & Traceability

- Counterfeit & Fraud Protection

- Personalization (Alphanumeric, Messages, Photography)

- Fast, Efficient, Effective

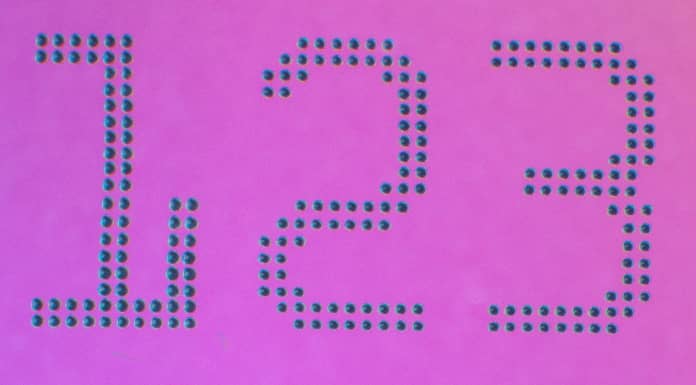

Types of Identifiers

- Company Branding

- Serial and Certificate Numbers

- Alphanumeric Data

- Barcodes

- Personal Messages

- Photography

- Decorative Designs

- And More!

Types of Inscription

SurfaceScribe™ inscription can be either invisible or visible. Using cold-laser technology, our lasers mark the girdle, crown or table facets of a cut diamond.

The Girdle is considered a neutral area that does not negatively impact quality, ideal for visible markings, which traditionally require a high-contrast black inscription.

Crown and Table facet markings require a shallow, transparent inscription.

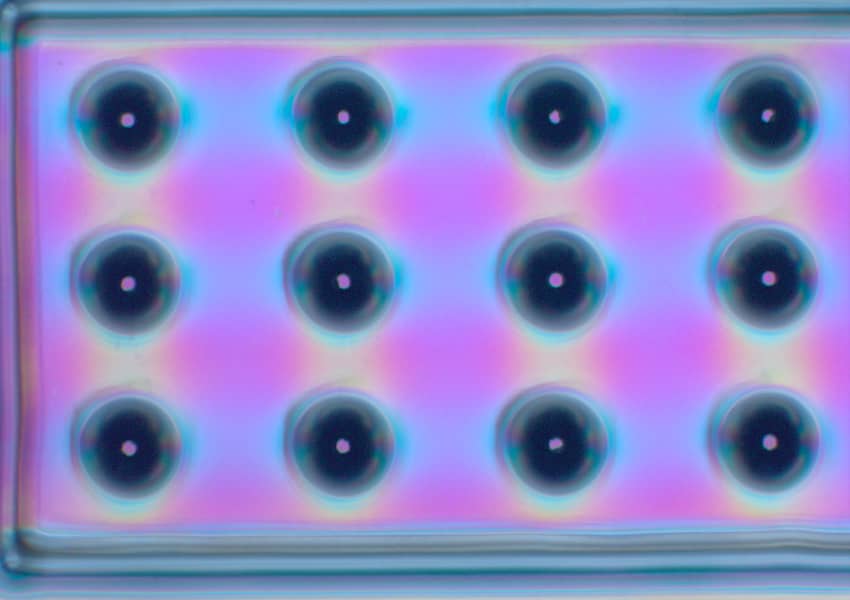

PermaScribe™ inscription uses sub-surface technology that can be invisible or visible, and inscribed within any area of the faceted diamond.

Visible PermaScribe™ mark is mainly used for lab-grown diamonds to support identification compliance and prevent inscription removal.

Invisible PermaScribe™ mark is used for both natural and lab-grown diamonds. Without affecting the diamond’s clarity, PermaScribe™ technology assists with identification and security measures.

Our Products

LMS SurfaceScribe™ Series

The LMS series provides the only commercially available cold lasers designed and optimized for the diamond industry. Cold lasers do not require pre and post-treatment, saving time and simplifying the marking process resulting in a precise mark with no damage to the stone. With high-contrast SurfaceScribe™ markings, these lasers inscribe both invisible and visible identifiers. Used by the industry’s leading labs and brands, the LMS series marks certification numbers, security marks, brand names, logos, photographs and more. The laser series is known for providing high-precision motion with extreme accuracy.

LMFT PermaScribe™ Series

Our LMFT PermaScribe™ laser provides a sub-surface inscription that can be visible or invisible under 10X magnification and inscribed on any area of the faceted diamond. This provides an extra level of protection by preventing the removal of the mark without dramatically altering the stone. The laser is part of solutions for diamond provenance, journey, identification, branding, supply chain security, personalization and more.

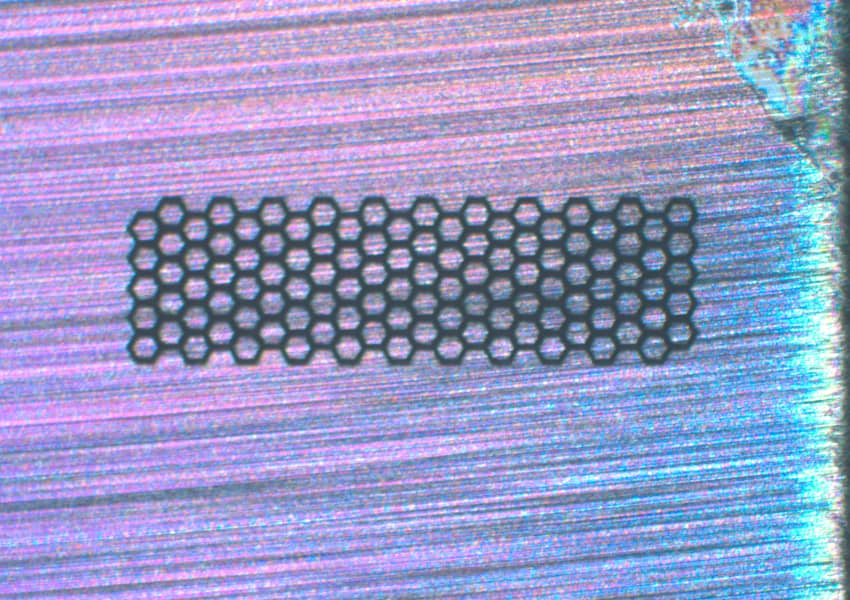

LMP Pico Cool Series

The LMP Pico Cool lasers are short pulse-duration systems used for the micro-machining and processing of diamonds. Available in several wavelengths, it’s considered a more affordable option to our LMFT PermaScribe™ laser for subsurface inscription.

What Can Lasers Do?

Mark

Engrave

Machining

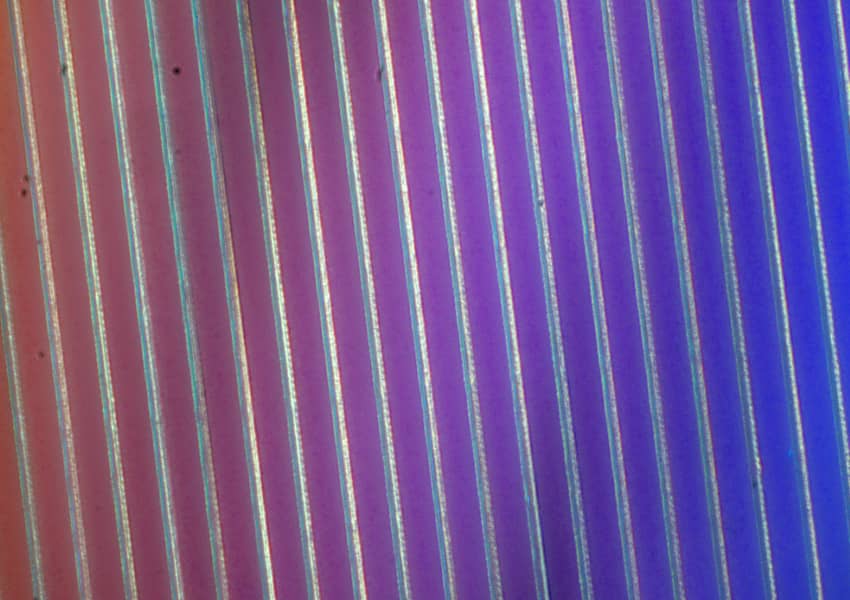

Surface Texturing, Patterning & Structuring

Diffraction Grating

Schedule Your Free Consultation Today

Discover how our cutting-edge laser technology can provide business advantages with a free consultation.